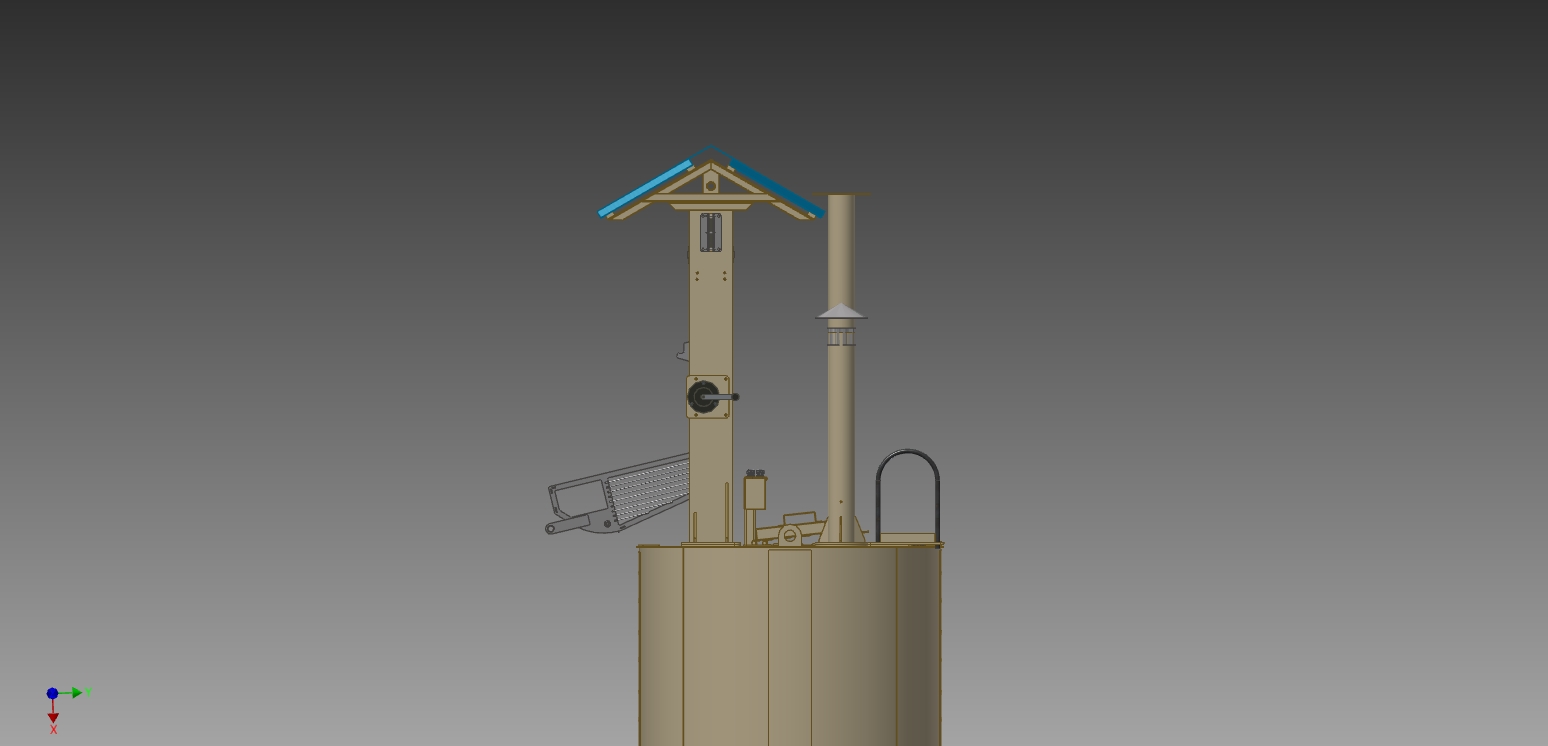

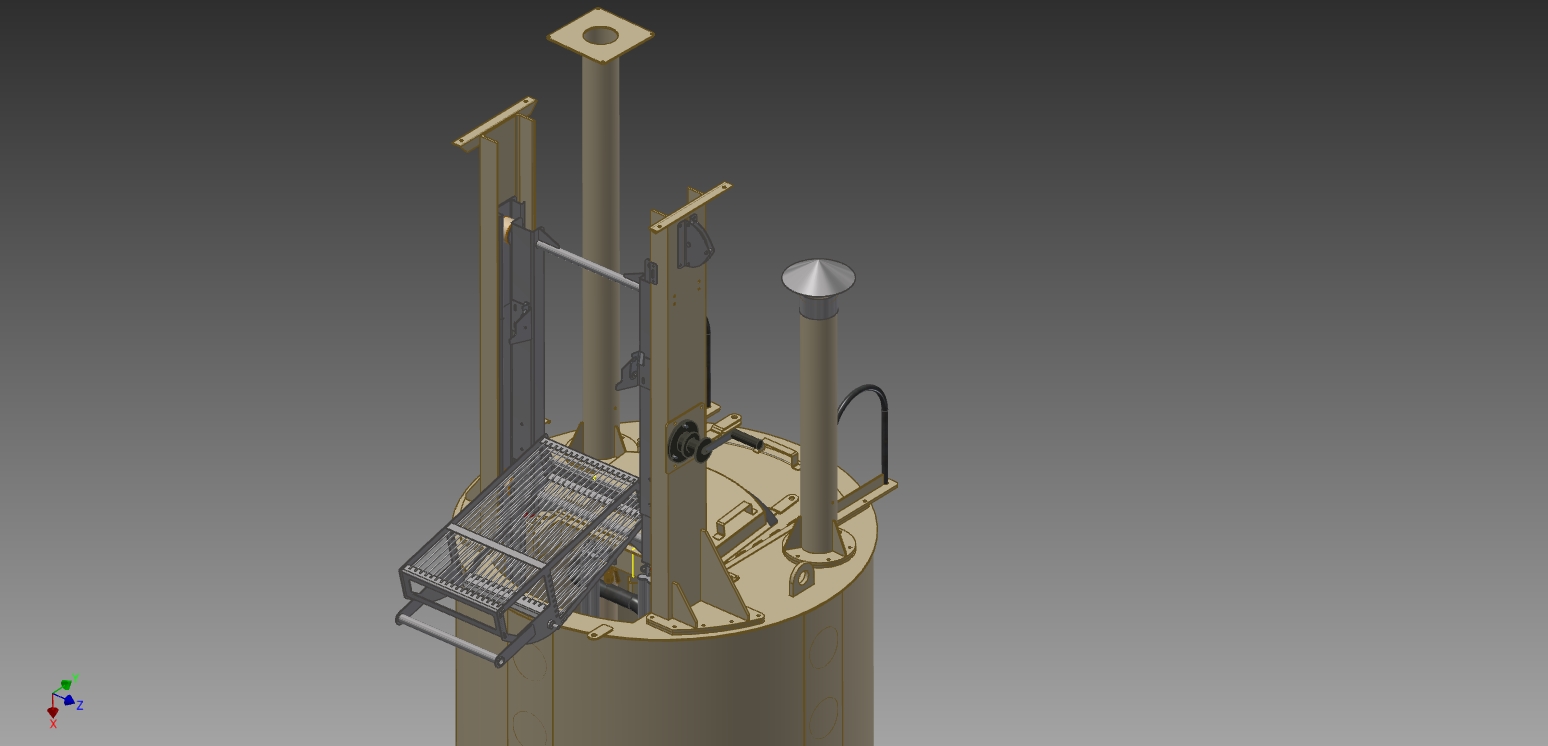

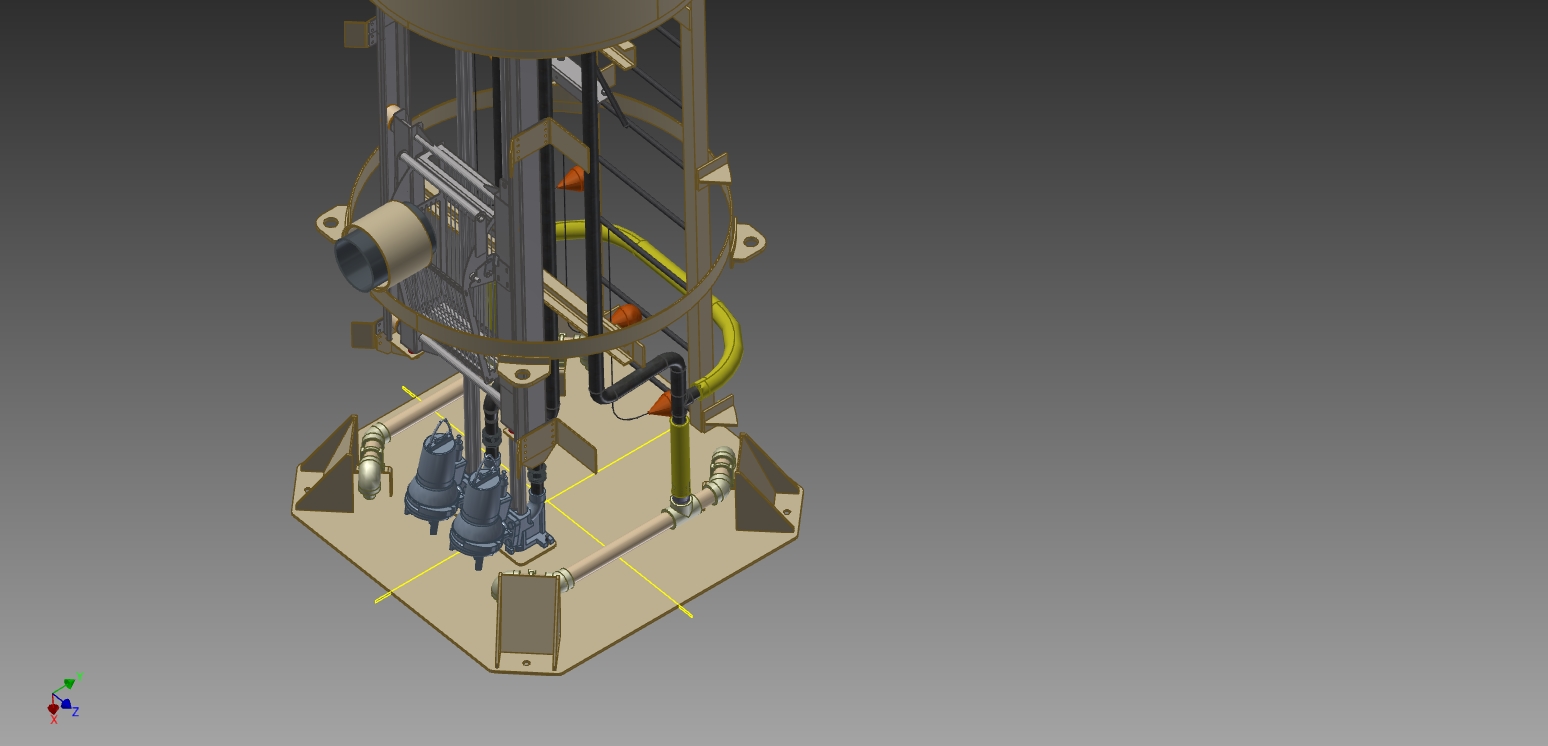

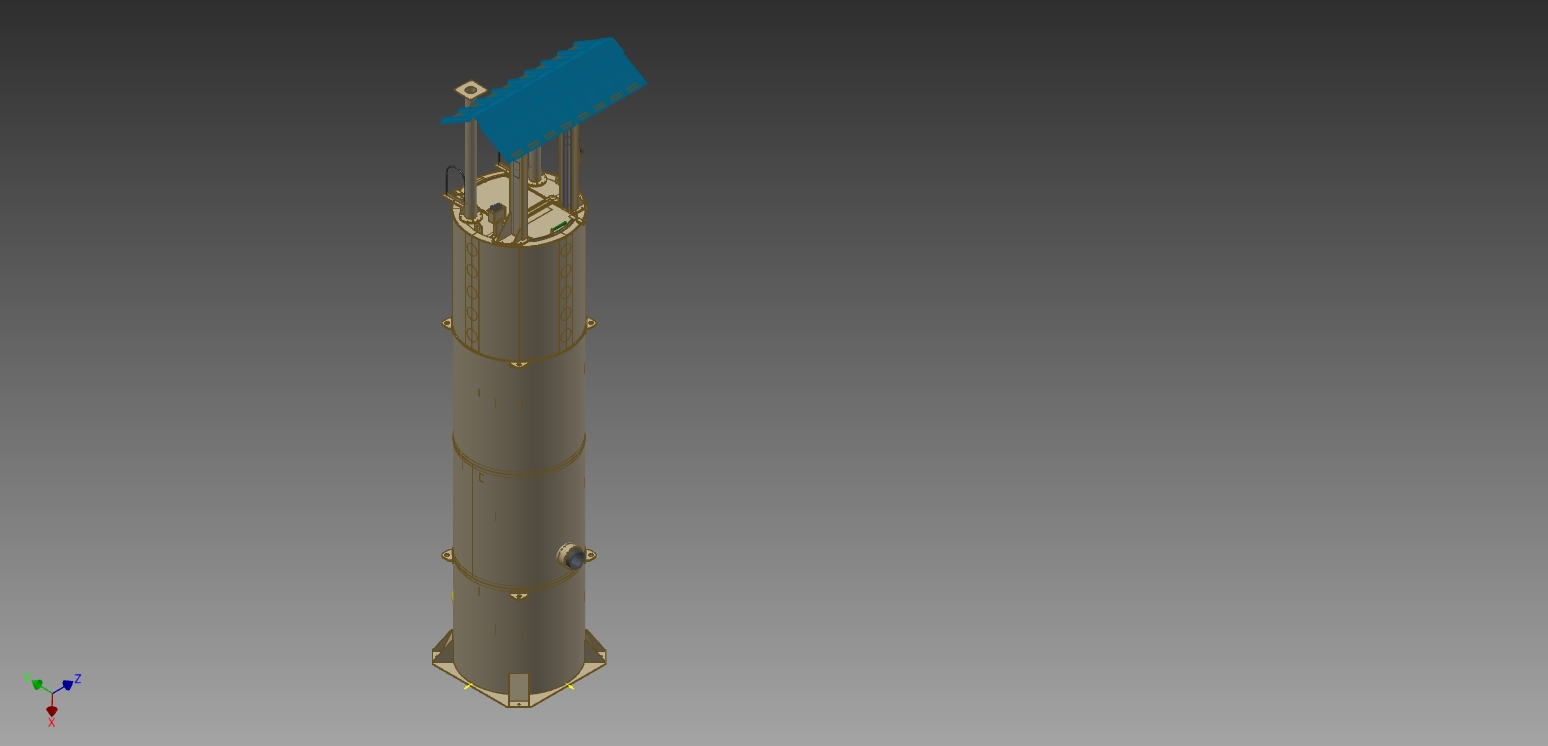

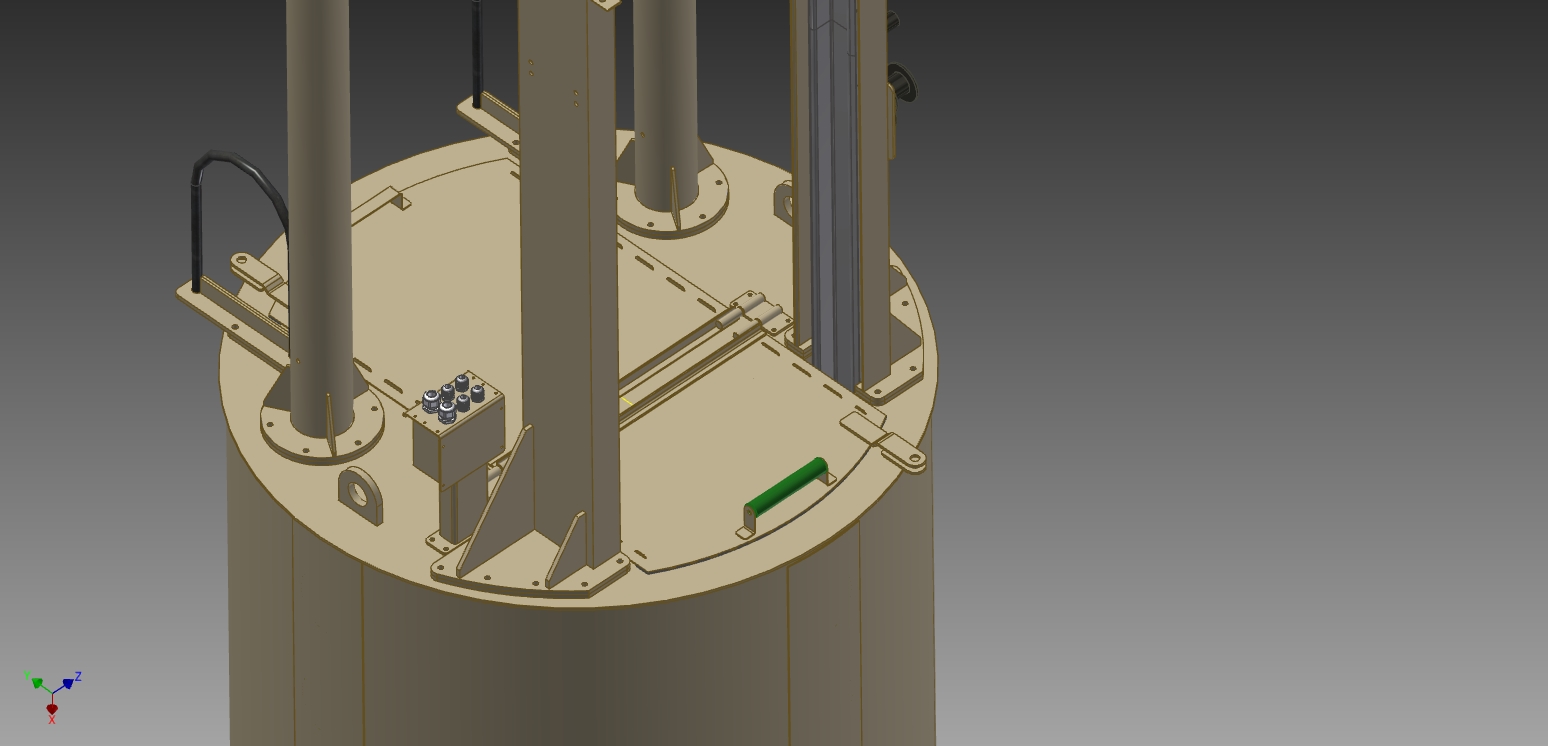

The Sewage pumping station (hereinafter SPS), is designed for pumping drainage, surface-rain, domestic, industrial and industrial wastewater in cases where the transport of liquid by gravity is impossible.

Sewer pumping stations solve everyday problems, the main one i improving the life quality of the population of certain areas and the possibility of developing new land plots (distant from the engineering infrastructure). The pumping stations made possible the development of new territories in swampy or flooded areas, and it became possible to channel far districts into urban sewer networks, lay sewer networks on complex terrains, and also the made it possible to create surfaces with a large drainage area for the construction of hard-surface areas (for example, roads and parking areas).